The installation involved IOW Group’s advanced centrifugal oil separator, a compact yet powerful system designed to remove microscopic contaminants from lubrication oil more efficiently than conventional filters. Unlike traditional full-flow filters, IOW’s centrifugal separator uses high-speed rotation to separate solids and debris from the oil without the need for replacement elements. This results in significantly cleaner oil, less component wear, and extended service intervals.

In the volatile world of maritime operations, equipment reliability is vital. For a Norwegian world leader in RORO shipping, and for Ugland (a family-owned shipping and offshore enterprise operating worldwide), ensuring optimal engine performance across their fleet is essential. That’s why both companies have turned to Scanvi-Interyards AS to upgrade their vessel oil filtration systems with IOW Group technology.

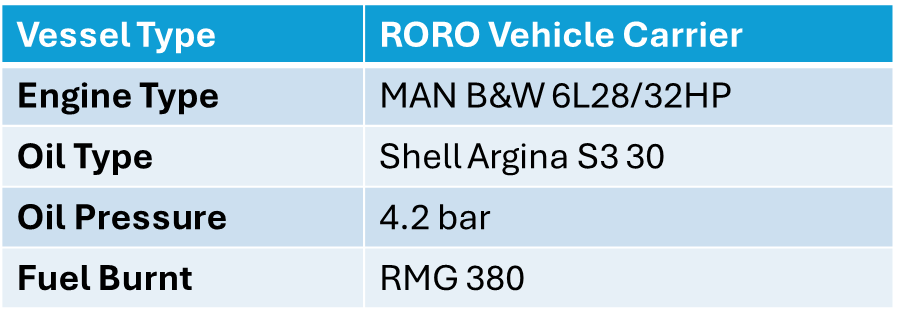

Installation Information: Norwegian World Leader in RORO Shipping

An IOW MP400 Centrifugal Separator with an SCU 0002 remote monitoring unit was installed onto a MAN B&W 6L28/32HP engine.

Setting Sail with Smarter Filtration

Quantifiable Benefits

Since installing IOW Group technology, the client has reported significant sludge removal from their lubrication system. Within 111 hours, the IOW MP400 removed 5000g of contaminants which would have been contributing to the degradation of the engine. More impressively, after a further 172 hours, another 4,500g of soot was removed.

Key outcomes include:

- Up to 50% reduction in oil change frequency

- Significantly improved oil cleanliness, extending equipment life

- Lower CapEx and fast ROI, often realized within months

- Reduced operational waste and maintenance needs

Installation Information: Ugland

Ugland installed an IOW MP200 centrifugal filter on an auxiliary engine on board their bulk carrier, MV JORITA. The aim was to achieve cleaner lubrication oil, reducing engine wear and boosting both reliability and efficiency. By adopting this advanced oil filtration technology, they’ve extended lube oil life, reducing oil change frequency and waste. This reinforces Ugland’s commitment to environmental and sustainable operations. Based on the successful results, they have decided to retrofit their entire bulk carrier fleet with next-generation centrifugal filters from IOW Group.

Intelligence at Sea: Remote Monitoring on Board

One standout feature is IOW Group’s remote monitoring capability. The performance of the centrifugal separator is monitored in real-time, notifying the maintenance team when the centrifuge needs to be serviced, enabling predictive maintenance rather than reactive servicing. This hands-off approach streamlines operations and ensures the separator is always working at peak efficiency, without relying on guesswork or manual checks.

Paving the Way for Sustainable Fleet Modernization

IOW Group’s success aboard multiple vessels is a compelling case in how modern filtration technology can deliver both immediate and long-term benefits. By embracing centrifugal oil separation, clients not only enhance the reliability of their engines, but they also take a step towards greener, more efficient fleet operations.

As the maritime industry faces increasing pressure to improve performance, reduce emissions, and manage costs, IOW Group’s solution represents a smart, scalable upgrade for any shipowner seeking to future-proof their fleet. Upgrade today.