In summary, IOW Group’s Centrifugal Oil Filters deliver exceptional performance, with the MP600 removing 5.5kg of sludge from lubrication oil in 427 hours. This leads to cleaner machinery, improved operational efficiency, and a significant reduction in maintenance frequency and associated costs. Furthermore, decreased sludge accumulation helps extend the lifespan of both machinery and primary filters, ultimately delivering a strong long-term return on investment (ROI) for the customer.

Overview

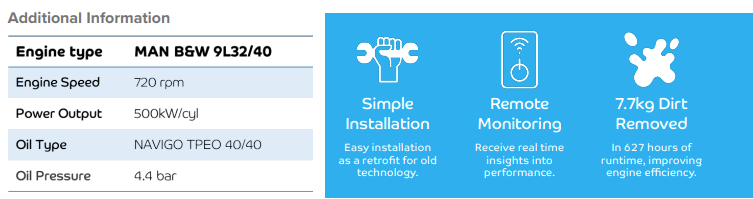

A client recently partnered with IOW Group to upgrade their lubrication system by replacing an old FM600 centrifugal separator with the superior IOW MP600 on a MAN B&W 9L32/40 engine. Thanks to IOW Group’s innovative bolt-off, bolt-on design, the retrofit was easy and efficient as a direct replacement, minimizing downtime and installation complexity. With the new MP600 centrifuge in place, the client will benefit from significantly improved contaminant removal, leading to enhanced engine reliability, greater operational efficiency.

Installation

Upgrading the oil filtration system with an IOW MP600 centrifuge is a simple and efficient process, thanks to its user-friendly bolt-on, bolt-off design. This allows for a seamless transition to a more effective filtration solution. Paired with the CentriClean SCU0002, clients can remotely monitor the performance of their MP600, a feature not available from other manufacturers. This remote capability enables engineers to ensure optimal operation of the centrifuge and receive timely service notifications, helping to maintain smooth and uninterrupted operations.

Results

Following an initial 200 hours of operation, the IOW MP600 successfully extracted 2.2 kg of contaminants from the engine’s lube oil system. After an additional 427 hours, it removed a further 5.5 kg of contaminants, demonstrating its ongoing effectiveness in maintaining oil cleanliness. Efficient removal of contaminants from lube oil is critical for protecting engine components, reducing wear, extending maintenance intervals, and ensuring overall system reliability and performance.

Conclusions