Overview

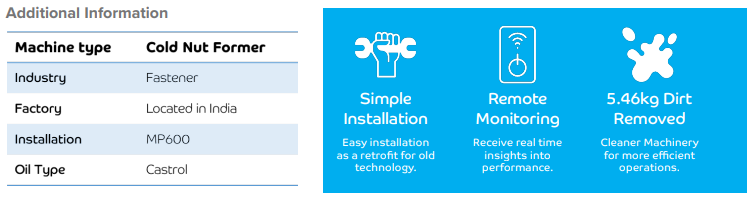

A client undertook a trial period with our IOW MP600 Centrifuge, which was installed as a retrofit on a High-Speed, five station Cold Nut Former. The objective was to assess performance differences and determine whether IOW Group’s separation capabilities could enhance machine reliability and performance. The machine uses Castrol Oil to lubricate its key components and is designed to keep operations running smoothly. However, after an extended run-time, the oil quickly became dirty, requiring scheduled maintenance and oil changes to ensure the factory continues producing fasteners (screws, nuts, bolts, rivets, washers, etc.) efficiently.

Installing an IOW MP600 Centrifuge onto a Forging Machine

Upgrading the oil filtration system with an IOW MP600 centrifuge is easy and straightforward. They have a bolt-on, bolt-off design to make transitioning to an efficient centrifuge a smooth process. With a CentriClean SCU0002, the client is able to monitor the performance of their MP600 remotely, which other manufacturers are unable to offer. This also provides the scope for engineers to ensure the centrifuge is running as expected and are notified when a service is required to keep operations running smoothly.

Results

After an initial runtime of 100 hours, 5.46 kg of contaminants were removed from the machine’s lube oil system. The centrifugal separator operated at 4,422 RPM under 6 bar of pressure, delivering robust and efficient filtration performance.

Equipped with IOW Group’s remote monitoring Separator Control Unit (SCU), the system proactively notifies engineers when maintenance is due, streamlining scheduled servicing. Unlike traditional centrifugal technology, the IOW Group separator features a user-friendly design that allows for easy disassembly and cleaning, significantly reducing downtime and maintenance effort.

By effectively removing large quantities of dirt from the lube oil, the separator dramatically enhances the machine’s reliability and longevity by reducing wear on critical components.

Conclusions

In conclusion, the IOW Group Centrifugal Oil Filters provide superior performance, with the MP600 effectively removing 5.46kg of sludge from lubrication oil within 100 hours. This results in cleaner machinery, significantly enhancing operation and efficiency, whilst reducing maintenance needs and costs. Additionally, the reduced sludge accumulation positively impacts the lifespan of machinery and primary filters, further contributing to a substantial return on investment (ROI) for the customer in the long run.