SMM Hamburg 2024

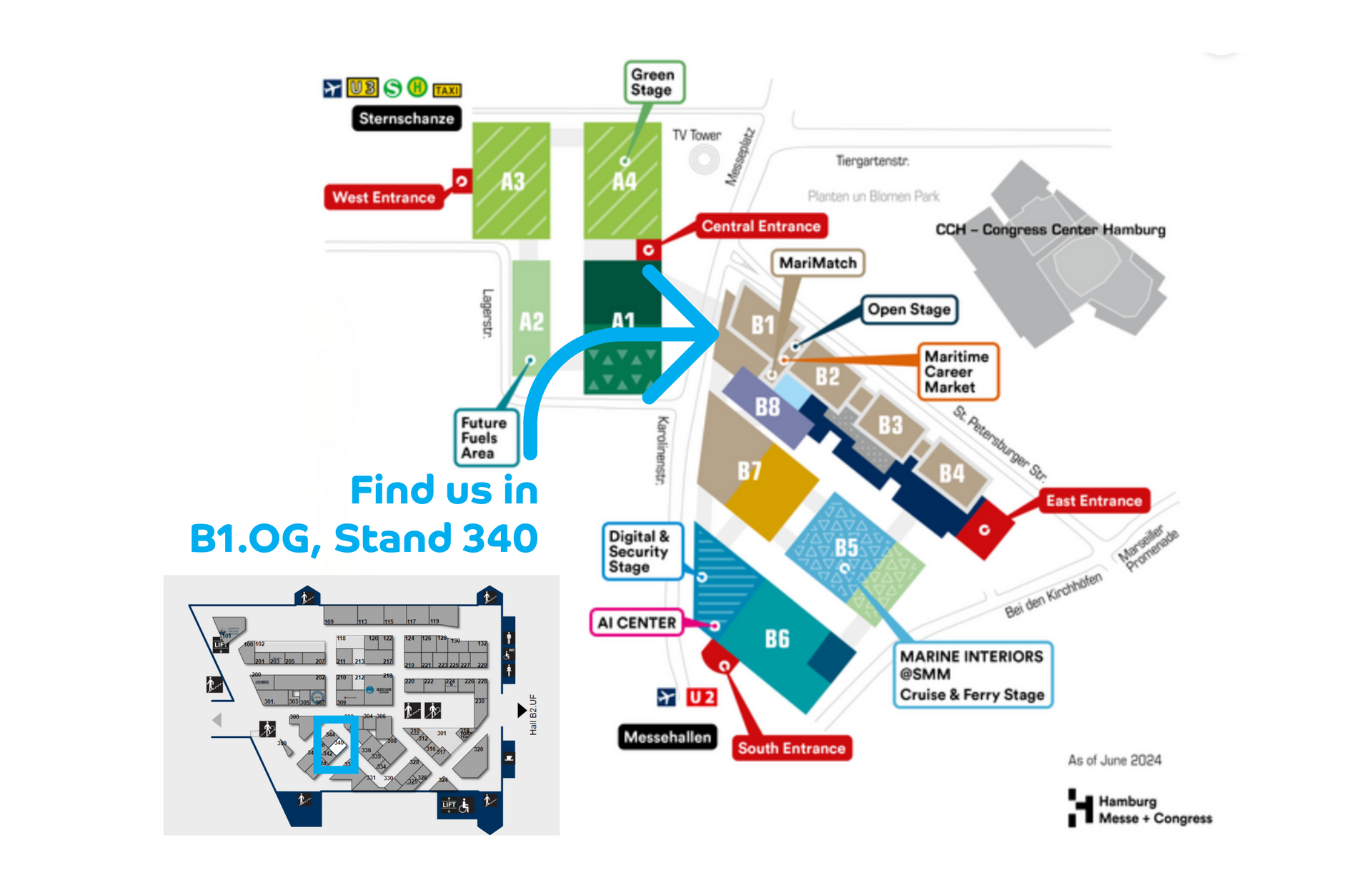

SMM Hamburg 2024 is being held at Hamburg Messe und Congress in Hamburg, Germany from September 3rd 2024 finishing on the September 6th 2024. Find IOW Group at B1.OG.340 where our team of experts are on hand to transform your oil filtration system. To register your interest and book a meeting with our team, please fill out the contact form below.

Find us in B1.OG, Stand 340

IOW Group are exhibiting at Stand B1.OG.340.

Want to know more about SMM Hamburg?

SMM Hamburg is the world's leading trade fair and conference event for the maritime industry that attracts 40,000 participants from over 120 countries. IOW Group are one of 2,000 companies exhibiting, presenting our state of the art technologies and services that are proven to transform oil filtration systems.

Visit IOW Group in B1.OG, Stand 340.

IOW Group Products

Customer Installations

Check out our successful customer installations on a variety of different engine manufacturers below.

If you are attending SMM Hamburg 2024 and would like to discuss improving your pumping and filtration setup, then please visit our team at B1.OG.340

Alternatively, fill in the contact form at the bottom of the page and we will be in touch.

Overview: YANMAR 8N21L-GV A client carried out a trial upgrade on an auxiliary engine lubrication system, replacing an existing GF-2 type centrifugal filter with an MP090 unit supplied by IOW Group. The system operates with a 1,200-litre oil sump capacity, using Shell Argina S240 lubricating oil while running on VLSFO 380 CST fuel. The objective of the trial was to assess whether the MP090 could deliver improved contaminant removal compared with the GF-2, while also introducing remote performance monitoring that had not previously been available

For today’s marine superintendent, filtration is no longer a background consideration. It’s a direct lever on reliability, cost control, and vessel availability. With tighter schedules, leaner crews, and rising pressure to reduce operating costs, the margin for error has all but disappeared. Every unplanned stop, every premature oil change, every maintenance-heavy system chips away at performance and profit. That’s where smarter filtration earns its place on board.

In today’s industrial landscape, where uptime is everything, Chief Engineers are facing growing pressure to keep vital equipment running efficiently while reducing maintenance costs. From marine and power generation to heavy transport and mining, reliability is the cornerstone of performance - and that’s exactly where IOW Group’s Centrifugal Oil Filter is making its mark.

In the wire extrusion industry, maintaining clean process oil is critical to ensuring consistent product quality, protecting equipment and minimizing downtime. Contaminants such as carbon, soot, metal fines, and degraded oil by-products can quickly compromise performance, leading to frequent filter changes, increased maintenance, and rising operating costs. Centrifugal oil filtration offers a proven, cost-effective solution to these challenges.

MAN engines are trusted worldwide for their engineering quality, long-lasting durability, and impressive fuel economy. They are used in vessels, power generation, and heavy-duty vehicles across multiple sectors, where dependable performance is essential. To ensure these engines continue running efficiently and to extend their working life, effective oil filtration is critical. One of the most reliable methods available is centrifugal oil filtration, which provides strong protection against wear and helps maintain the smooth, consistent operation of MAN engines. This article explores why this filtration technology plays such a vital role in keeping them at peak performance.