Location: USA

Industry: Trucking

Engine Type: CAT 3406

Model Installed: IOW MP090 Centrifuge Filter & CentriClean SCU0003 Monitoring Unit

Background Info

This 2015 Kenworth W900L truck owner wanted to improve the quality of the lube oil supplied to the CAT 3406 engine. By installing an effective centrifuge filter, the lube oil could be cleaned to a standard that would reduce the wear on engine components. This driver uses 15W-40 lubrication oil. The engine oil pressure is 70 PSI pressure (4.8 Bar). Oil changes were being performed after 15,000 miles driven. Reducing engine wear will maximize the lifespan and performance of this engine. Thanks to regular oil analysis, we were quick to see positive results on this installation!

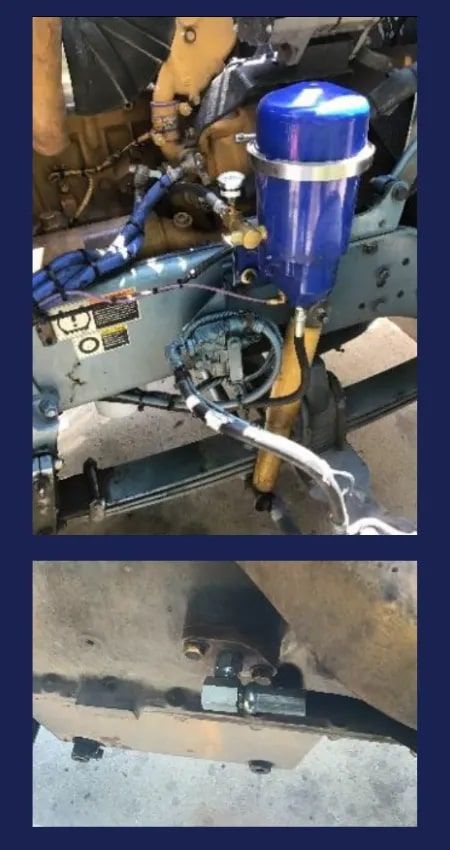

An IOW MP090 centrifuge filter and CentriClean remote monitoring unit were installed on a Kenworth truck

Installation

The 2015 Kenworth W900L truck required an IOW MP090 centrifuge filter with a pressurized drain system (PDS). The air supply to the PDS was set at 35 PSI (2.4 Bar). It was securely mounted to the frame rail, and the inlet/outlet hoses were securely fastened to avoid moving parts.

The IOW centrifuge is the only product of its kind to offer a choice of remote monitoring units. These separator control units (SCUs) work with the centrifuge providing unique control and insight to increase filtration performance. For this CAT 3406 engine installation, the driver selected the CentriClean SCU0003 model. The CentriClean SCU0003 connects via Bluetooth to the centrifuge filter to provide live data and information within the CentriClean App (available for Android and Apple devices). The remote monitoring unit was installed inside the cab of this Kenworth truck, meaning it’s easy for the centrifuge performance to be monitored by the driver. Live data, alarms, and manuals within the CentriClean App are the perfect product for truckers who are always busy and need information immediately.

Thanks to the CentriClean SCU0003 unit, the IOW MP090 centrifuge RPMs are provided to the truck driver. At the installation time, the IOW MP090 centrifuge filter was at 60 PSI pressure (4.1 Bar) and rotating at 4,494 RPMs. With 70 PSI pressure (4.8 Bar), the IOW MP090 centrifuge filter was recorded turning at 6,0006 RPMs.

The IOW MP090 centrifuge filter was mounted to the frame rail (top image), and a pressurized drain system (PDS) return (below image).

The Results

Analyzing oil samples is key in measuring the results in performance of the IOW centrifuge filter. This driver was keen to see the improvement in lube oil cleanliness and arranged oil analysis over a 3 month period so the scientific data could be reviewed.

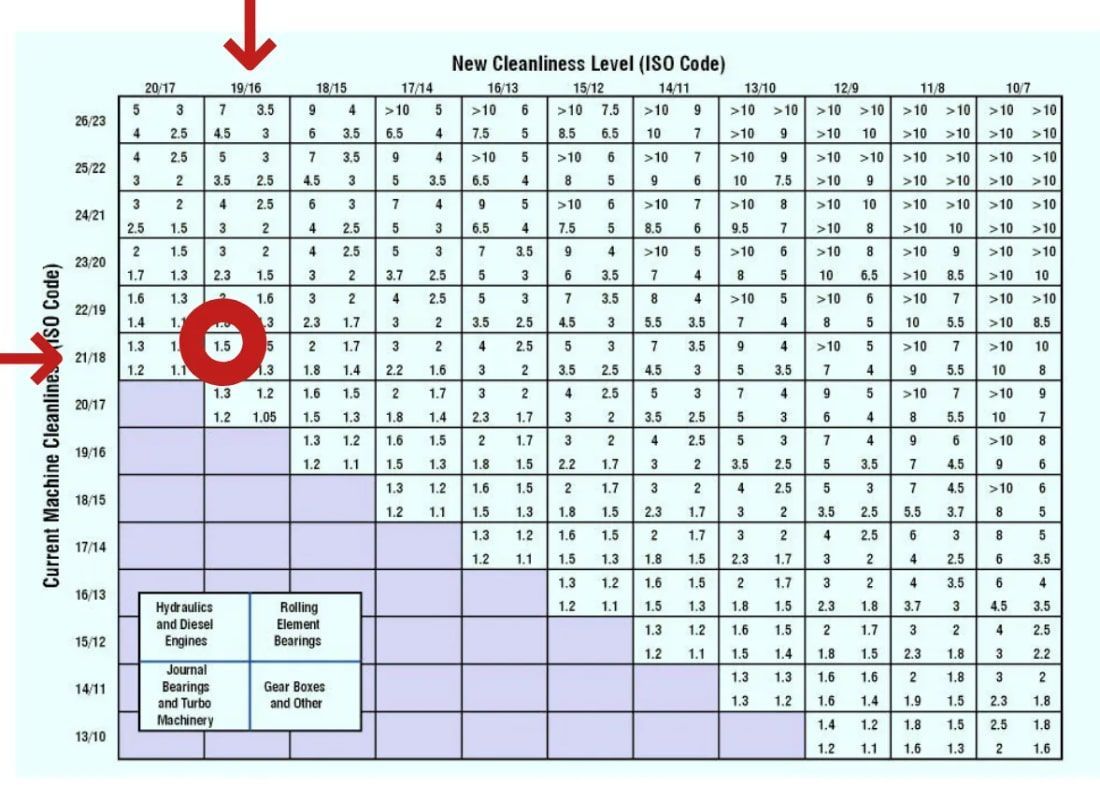

Contaminant levels within the engine oil are measured and represented using ISO cleanliness codes. The ISO cleanliness codes are derived from the International Standard ISO 4406:2017. The ISO code shows three sets of separated numbers. Reviewing these codes at regular intervals gives a good indicator of the condition of the oil and can also assist in calculating how these improvements impact the machinery.

On this CAT 3406 installation, the initial ISO cleanliness code was 21/18/12. Three months later, the oil cleanliness had dramatically improved thanks to the use of the

IOW MP090 with a new ISO cleanliness code of 19/17/12. This difference is illustrated in the chart below.

On this installation the ISO cleanliness codes improved from 21/18/12 to 19/17/12 helping to extend machinery lifespan

Customer Feedback

With the customer's main focus being oil cleanliness, the driver was extremely happy with the outcome. The improved ISO cleanliness codes meant the CAT 3406 engine components were protected from excessive wear due to the contaminants present in lube oil. As a result, the maintenance required on this CAT 3406 engine is reduced.

Thanks to the CentriClean SCU0003, the driver can see the performance of the centrifuge filter and be confident that the oil is being filtered to the highest standard. This reduces man-hours spent on investigating if the filter needs servicing as the information is available instantly in the palm of your hand.

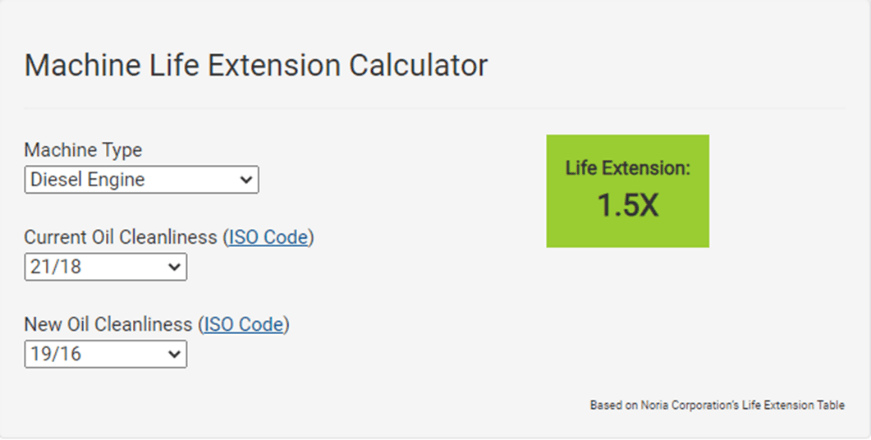

By improving ISO cleanliness codes the CAT 3406 engine lifespan is increased x 1.5

Conclusion

Lube oil analysis showed an improvement in the ISO cleanliness code from 21/18/12 to 19/17/12, which is fantastic. What did these codes mean in relation to the truck?

When the ISO cleanliness codes were inputted in the Noria machine life extension calculator, it showed the engine lifespan had increased x 1.5! By investing in an IOW MP090 centrifuge filter, this driver has protected the future of his most precious asset. The total cost of ownership (TCO) is reduced, and engine reliability is increased by 50%.

Another brilliant outcome for this IOW Group customer, we were happy to help this driver’s engine runs smoother for longer, ensuring many more happy miles driven for this trucker!

Do you want to protect the future of your engine?

Then fill in the contact form below to hear from one of the team at IOW Group about how our products can help you.