Location: Mexico

Industry: Natural Gas Compression

Engine Type: CAT G3608

Model Installed: 2 x IOW MP200 Centrifuge Filters & CentriClean SCU0002 Monitoring Units

Background Info

Natural Gas Compression sites put lubrication oils under extreme pressure, with differentiating temperatures and pressures throughout processing. As a result, high levels of contaminants are found in the lube oil system of these CAT G3608 engines. This site used SAE 40 lubrication oil. The engine oil pressure is 85 PSI pressure (5.86 Bar). The oil volume of these large natural gas engines is 800 liters (211 gallons). This customer wanted to effectively remove micron-sized particles such as sludge, wear material, and soot from the oil. By opting for an IOW centrifugal oil separator, this customer substantially increases the lifespan of the CAT G3608 engines, amongst other great results found below.

An IOW MP200 centrifuge filter and CentriClean remote monitoring unit were installed at a Natural Gas Compression site.

Installation

Due to the size of the lube oil system, two (2) IOW MP200 centrifugal oil separators were required to clean the oil efficiently. Alongside the centrifuge filters, the customer opted for two (2) CentriClean SCU0002 remote monitors to be installed that would allow access to live data via the front screen on the unit. As well as displaying the RPM of the centrifuges, the monitoring units can set alarms based on various factors. Access to this data allows the customer to measure the performance of the centrifuges and schedule cleaning/servicing accordingly. By utilizing remote monitoring and shifting towards a proactive maintenance approach, the customer will save on man-hours and maintenance budgets.

The two centrifugal separators were installed on a double mounting bracket with a large gravity drainpipe on the inspection platform. The inlet oil is taken from a 1-inch plug by the lubrication pump and connected to the IOW MP200 centrifuges by a flexible hose.

When installed, the first

CentriClean SCU0002 displayed 6,438 RPMs at 85 PSI (5.86 Bar). The second

CentriClean SCU0002 displayed 6,318 RPM and 84 PSI (5.79 Bar) lube oil pressure.

The two IOW MP200 centrifugal filters were installed on a double mounting bracket

The Results

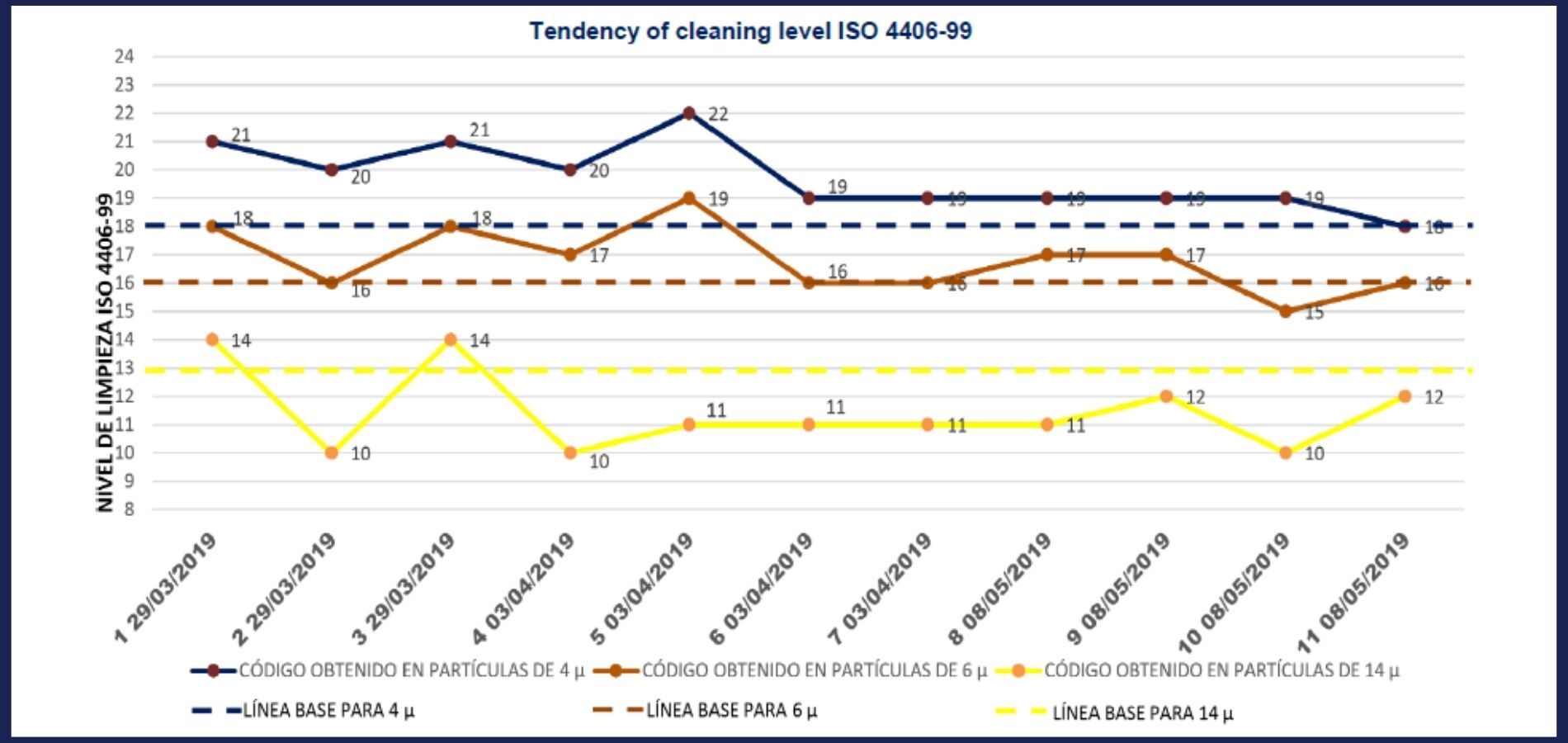

Regular oil analysis and ISO cleanliness codes are a great way to highlight the results and performance of the IOW centrifuge. The ISO codes indicate if oil is still purposeful for use and can also predict how improved oil quality can extend the engine's lifespan. The ISO cleanliness codes indicate contamination levels within the lube oil and include data such as particle counts.

Before installation at this Natural Gas Compression plant, the ISO cleanliness codes were 22/19/11. After installing the two IOW MP200 centrifuge filters, the ISO codes improved significantly to 18/16/12!

According to Caterpillar's advice, the recommended cleanliness level baseline for this engine is 18/16/13. The results achieved with the IOW MP200 centrifuges remain in line with these recommendations from Caterpillar, as illustrated in the graph below, and the oil was fit for continued use.

On this installation the ISO cleanliness codes improved from 22/19/11 to 18/16/12 which is within Caterpillar baseline guidance.

Conclusion

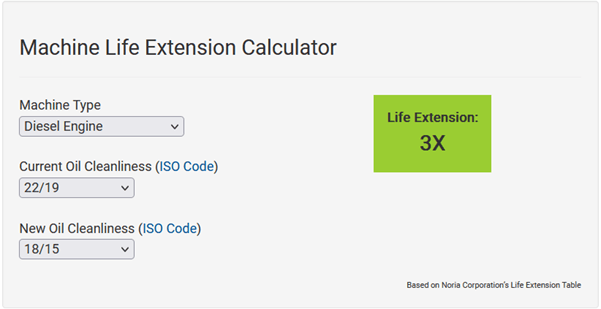

Using the ISO cleanliness codes, we were able to establish how the results would affect the engine lifespan.

By inputting the data into Noria's Life Extension Table, we calculated the improvement in ISO codes from 22/19/11 to 18/16/12. The CAT G3608 engine lifespan would be tripled (X 3)!

By improving ISO cleanliness codes the CAT G3608 engine lifespan was tripled ( x 3)

Customer Feedback

The improvement in ISO codes was substantial for this CAT G3608, tripling the engine lifespan. Keeping within the engine manufacturer's recommendations meant this customer was confident in the benefits gained by installing the IOW MP200 centrifugal oil separators.

Not only is the engine going to last for much longer, but there are many far reaching effects from upgrading the centrifugal technology. Primary filter life will be extended, oil change intervals are extended, and by removing the contaminants present in the oil, the engine components are saved from excessive wear.

As a result of the improved oil quality, less maintenance is required. Therefore, less man-hours are spent on these engines. Ultimately creating significant savings and increased reliability for this Natural Gas Compression plant.

Do you want to improve the reliability of your engine?

Fill in the contact form below to hear from one of the team at IOW Group