Sea Japan International Maritime Exhibition and Conference is being held at Tokyo Big Sight, East Hall 1-3, from April 10 - April 12, 2024. IOW Group is exhibiting at Stand 3C-01.

IOW Group is exhibiting at Sea Japan on April 10 - April 12 2024 in Tokyo, Japan.

What is Sea Japan?

Sea Japan is held every two years where shipbuilding and shipping experts gather together to showcase the very latest marine technology, and to meet partners and suppliers from around the world. Since 1994, Sea Japan runs various themes that match the trends of the time, with this year's theme focusing on clean energy. Visit IOW Group at Stand 3C-01 to see how we could help your organization improve efficiency and reduce emissions.

IOW Group's Mission

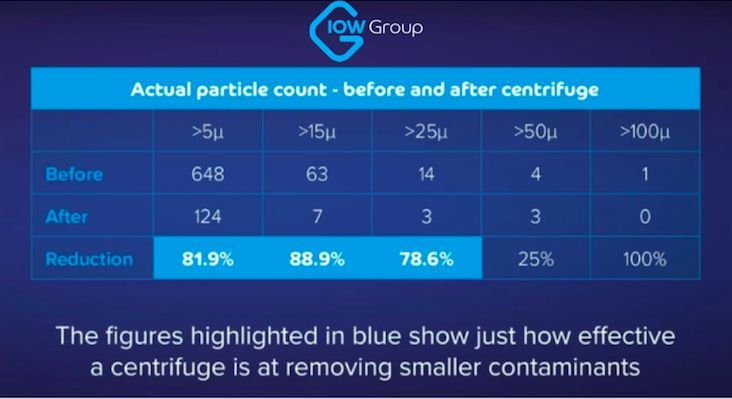

The IOW Group is an experienced and trusted manufacturer with over 100 years of combined experience in the lubrication sector. Our passion is to improve reliability and efficiency within organizations through our products. IOW centrifuges enhance the quality of lubrication oil by removing the maximum amount of contaminants. Utilizing unique patent-protected technology, the IOW centrifuges are 150% more efficient than any other centrifugal oil filter available!

Improving the quality of your lube oil by using a centrifugal filter can significantly impact processes within your organization.

- Reduced oil consumption

- Reduced machine downtime

- Reduced maintenance time

- Reduced man-hours

- Increased productivity

IOW Group centrifugal filters are designed for forward-thinking organizations who are searching for cleaner and more sustainable options to improve efficiency. If this sounds like you, then make sure to come and discuss how we can help you at Stand 3C-01.

Would you like to learn more about how our products can help? See some example case studies below or visit our installation webpage, where many case studies and installation bulletins are available.

IOW oil cleaning centrifuges are patent-protected and out perform old centrifugal technology.

Centrifugal Oil Filters:

The IOW centrifuge is a centrifugal filter like no other. Redesigning a product previously not updated since the 1950s, our skilled team of engineers made the IOW centrifuge filter with various features to improve performance, reliability, and efficiency!

The IOW centrifuge filter has been designed to stop the mixing of clean and dirty oil, with contaminated oil entering at the base and clean oil exiting through the top of the unit. This helps to avoid cross-contamination and means harmful particles do not enter back into circulation of the engine.

Bowl disc technology

IOW Group's bypass centrifuge filters utilize unique bowl disc technology. Unlike conventional centrifugal spinners/separators, IOW Group centrifuge filters have a central bowl disc stack that increases the separation efficiency, dramatically reducing the time that contaminants stay in the oil. The bowl discs provide more surface area meaning finer separation and filtration can occur. Bowl disc dramatically speeds up the precipitation of the solids from the liquid.

The IOW range of centrifuges is patent protected and contains unique features to improve filtration performance

Remote monitoring

IOW Group bypass centrifuge filters have dirt/sludge monitoring technology, which informs the operator when the separator needs servicing, saving valuable personnel time on, otherwise unnecessary, cleaning. The CentriClean remote monitor is Modbus or Bluetooth compatible and can be easily connected to your existing alarm systems. With the use of remote monitoring units, the user has the benefit of always being able to measure the centrifuges' performance and accordingly schedule services. This feature is not available with any other centrifuge filter and brings centrifugal technology to the 21st century!

Market-leading performance

IOW centrifuge filters allow you to maximize performance, extend maintenance intervals, and reduce the total cost of ownership (TCO) for engine systems and auxiliaries. IOW centrifuge filter comes standard with bowl disc technology and external monitoring for greater efficiency. Our centrifuge filters have also been designed to retrofit to existing pipework, so upgrading to this superior technology couldn’t be easier.

Our centrifugal technology is 150% more efficient than any competitors and provides superior protection for engines and auxiliaries from harmful contaminants.

Come and see one of our knowledgeable team at Stand 154 to find out more and discuss your requirements.

An IOW centrifuge filter removes the maximum amount of harmful contaminants from lube oil to protect engines from excessive wear

If you are attending Sea Japan International Maritime Exhibition and Conference and would like to discuss our filtration solutions, then please visit our team at Stand 3C-01.

Alternatively, fill in the contact form at the bottom of the page, and we will be in touch.