Industry: Marine

Engine: MTU Series 2000 M72

Model Installed: IOW MP090 Centrifugal Oil Filter & CentriClean SCU0003 Remote Monitor

The IOW MP090 oil centrifuge and CentriClean SCU0003 remote monitoring unit were installed onboard a wind farm support vessel

A Brief History:

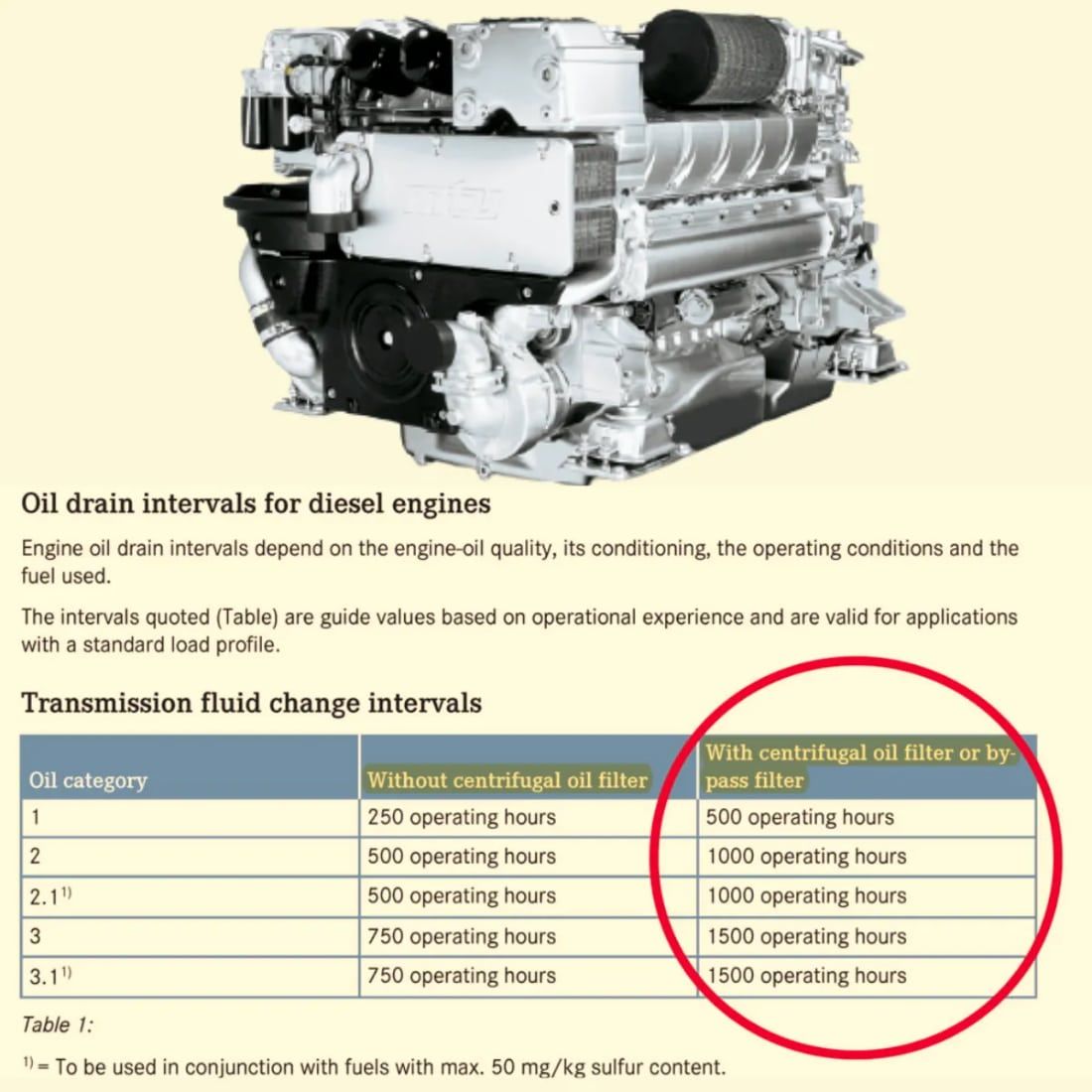

MTU engines have been popular and trusted across various industries with a particular focus on marine applications. MTU is the core brand of Rolls-Royce Power Systems, a worldwide leader in providing high-efficiency diesel engines for the most demanding requirements. The MTU Series 2000 M72 is a market-leading engine for the high-speed ferry market. These engines are light, compact, and well suited for small engine rooms. The MTU series 2000 offers high efficiency and low fuel consumption over the entire range. MTU recognizes the benefits of having an effective centrifugal oil filter fitted to an MTU Series 2000 M72 engine. Engine oil drain intervals depend on the engine-oil quality, its conditioning, the operating conditions, and the fuel used. Per the MTU Series 2000 M72 manual, adding a centrifugal oil filter (bypass filter) to the engine will double engine oil operating hours.

The Installation

Our customer wanted to improve the filtration and quality of the lubrication oil onboard a catamaran wind farm support vessel. The catamaran had an MTU Series 2000 M72 engine running at a speed of 2250 rpm and a power of 1080 kW. Fueled by marine gas oil (MGO), this engine had old centrifugal technology that needed replacing to improve efficiency and give the MTU Series 2000 engine the best protection available from contaminants in the lube oil. The Fuchs Titan SAE 15W-40 lube oil was being used at a temperature of 82°C (180°F). It was decided the best model centrifuge for this MTU series 2000 engine would be the IOW MP090 centrifugal filter along with a CentriClean SCU0003 monitor (Separator Control Unit). The IOW MP090 centrifuge filter was installed in the engine room with the CentriClean SCU0003 monitoring unit fitted above for easy access. The short and long terms benefits of remote monitoring units are great. Our customers can be confident the centrifuge is running optimally with the ability to set alarms. The CentriClean SCU0003 monitoring unit also has the benefit of providing live data via the CentriClean App and ordering spares and viewing manuals. Utilizing this new monitoring technology means fewer resources are used but with better results!

The IOW MP090 centrifugal oil filter was installed in the engine room with the CentriClean SCU0003 unit fitted above

The Results

Once the IOW MP090 centrifugal oil filter was installed on the MTU series 2000 M72 engine, an alarm was set via the CentriClean SCU0003 monitoring unit to alert the operator after 200 run hours. Once the run-hours had completed the IOW MP090 centrifugal oil filter was cleaned and the sludge that had collected on the inner bowl wall was weighed. The contaminants removed from the lube oil within the first 200 run hours weighed 152 grams (0.34 lbs)! Equaling a dirt removal rate of 0.76 grams per hour.

The IOW MP090 centrifugal oil filter ran for 459 run-hours for the second test through varying engine speeds and oil pressure. Due to the CentriClean SCU monitoring unit it was possible to record the centrifuge RPMs during the test (see table below). After 459 hours, the IOW centrifuge filter had removed 275 grams (0.6 lbs) of contaminants from the engine oil.

After 200 run-hours the IOW MP090 had drawn out 152 grams of contaminants from the lubrication oil

The Products:

The IOW MP090 Centrifuge Filter

The IOW MP090 centrifuge filter has been designed for an oil sump capacity of 15-90 liters (3.3-20 gallons). The IOW centrifuge filter turns faster than any existing market product creating a faster and better separation process. The higher speeds of the IOW centrifugal filter separate solids from the lubrication oil more effectively than any other centrifugal oil filter on the market.

The IOW centrifuge bowl is completely sealed, avoiding any cross-contamination between cleaned and dirty oil. The IOW MP090 centrifuge filter has a central disc stack, which significantly improves the efficiency of the separation process. Combining these unique features makes the IOW centrifuge oil filter 150% more efficient than any currently available product. All these features of an IOW centrifuge filter are patent protected; therefore, they are only available through the IOW Group.

The CentriClean SCU0003 Remote Monitoring Unit

The CentriClean SCU0003 remote monitoring unit is designed to monitor the performance of the centrifuge. This particular model is ideal for those operators who want access to live data at their fingertips! Using the CentriClean app, users can connect via Bluetooth to the SCU unit to access information and data.

Within the CentriClean app, the operator can set the speed of the centrifuge (RPM), set alarms for run-hours completed or if there is a drop in performance, or if servicing may be required. Multiple CentriClean SCU0003 units can be connected to the app, making it easy to set, control, and log the centrifuges without needing to physically see each centrifuge. Manuals are also available with the CentriClean app, where you can place orders for spare parts directly with us. Notes can be placed within each SCU profile on the app, making it easy to communicate within a team. Remote monitoring uses fewer resources and ensures higher performance from your centrifuge. The IOW centrifuges are the only product of its kind to offer a choice of remote monitoring units.

The IOW MP090 centrifuge oil filter is suitable for a sump capacity of 15-90 liters and is available with a choice of remote monitoring

The CentriClean SCU0003 monitoring unit connects via Bluetooth to the CentriClean App to ensure optimal performance of the centrifuge