A Brief History:

MAN marine engines have incredibly economical fuel consumption with powerful acceleration. Developing their first diesel engine in 1897, MAN is a well-known and trusted engine manufacturer. MAN engines are robust yet compact engines used throughout a variety of industries. The MAN L21/31 engine is a reliable power source that runs on heavy fuel oils (HFO). The design of the MAN 9L21/31 is compact and rigid for high safety. The MAN 9L21/31 has long overhaul intervals and is often used for ship propulsion and generator sets. The MAN 9L21/31 has a speed of 1000 r/min, a power covering 1290-1935 kW, and minimum oil consumption of 192 g/kWh. The MAN 9L21/31 engine has excellent power and is an economic engine choice.

The Installation:

CMA CGM has been working with us to improve the cleanliness and efficiency of their lubrication systems onboard some of their vessels. The container vessel (ANL Wyong) had the original engine-supplied centrifugal bypass filters fitted and wanted to upgrade its bypass oil centrifuges. Filters and applications that come fitted as standard when purchasing engines are not the best at protecting your engine. Opting to replace the standard OEM-supplied centrifugal bypass filter with a superior product can have a massive impact on the overall health of your machine.

The vessel has MAN B&W 9L21/31 engines fueled with HFO RMK 500 (heavy fuel oil) running at 5 bar pressure (72.5 PSI). The MAN 9L21/31 engine has an oil capacity of 1,100 liters (242 Gallons), and CMA CGM uses Total Aurelia T1 4030 engine oil for lubrication.

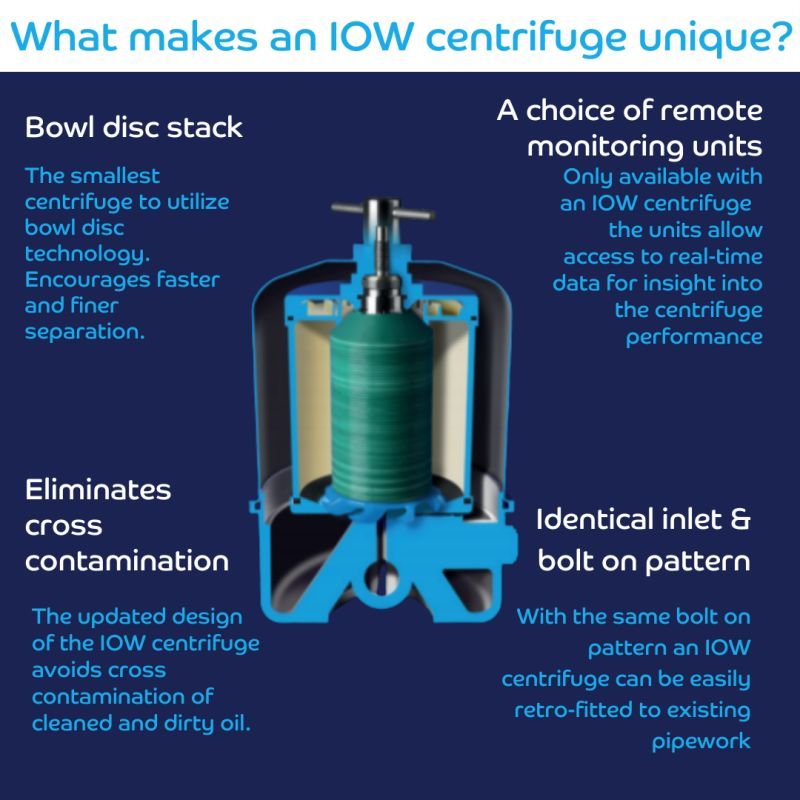

Knowing this information about the engine, we were able to advise the installation of an

IOW

MP600 centrifugal bypass filter. The IOW centrifugal bypass filters are designed to be fully interchangeable with current products on the market. This allows for retrofits to existing mountings without any modifications and makes installing the

IOW MP600 centrifuge filter quick and easy.

The Results

The centrifugal bypass filter was successfully installed on the MAN B&W 9L21/31 engine onboard the ANL Wyong container ship.

After 655 run hours, the IOW MP600 bypass filter was serviced and cleaned. The sludge cake removed from the centrifuge bowl weighed 3.5kg which was a great result.

The oil was then topped up with 560 liters (123 gallons) of new lube oil. The IOW MP600 ran for another 186 hours cleaning the lubrication oil. After just 186 hours, the IOW centrifugal bypass filter had removed another 3kg of harmful contaminants from the oil! Calculating a dirt removal rate of 16 grams per hour!

Compared to the performance of the original standard centrifugal bypass filter, our customer informed us the IOW centrifugal bypass filter had removed (3) three times the amount of contaminations (in the same time period).

Additionally, the lube oil cartridge filter life had been increased by 60% due to the continuous cleaning of the lube oil. The lifespan of the generator engine sump oil was increased by 30-50%, and all the centrifugal bypass filter parts were found in good condition after all the run hours.

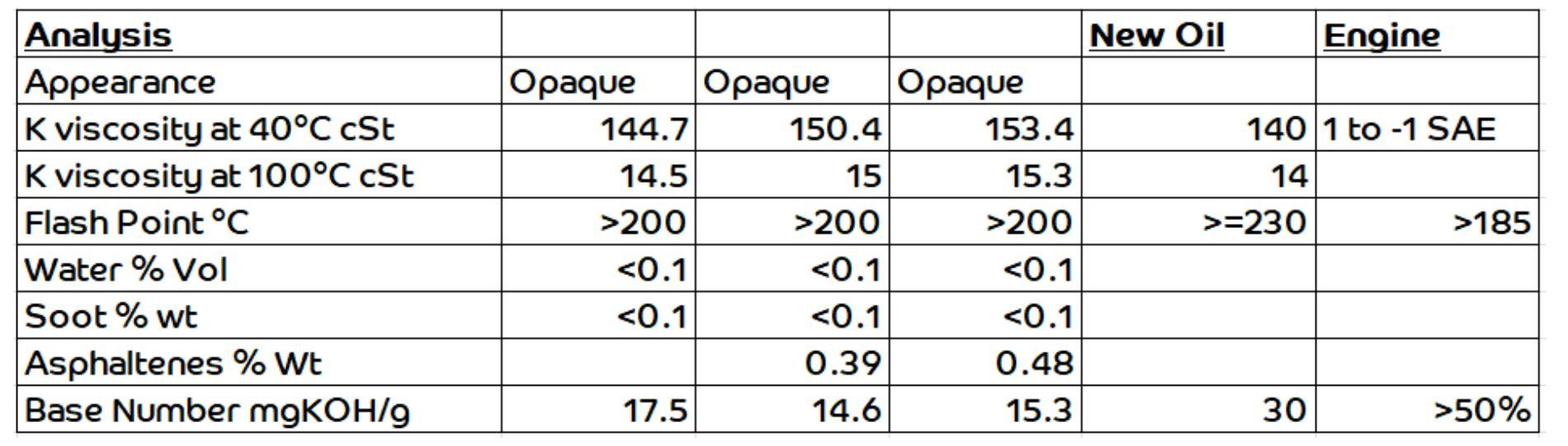

The crew onboard MV ANL Wyong also informed us that the IOW centrifugal bypass filter had halved the lube oil's asphaltenes. Data from a sister's vessel showed asphaltene levels at 0.79%, whereas by installing the

IOW MP600 centrifugal bypass filter, the asphaltene levels had dropped down to between 0.39%-0.48%. Removing these harmful asphaltenes helps prevent damage to your crucial engine components.

See the full results below:

The Products:

The IOW MP600 Centrifugal Bypass Filter

The IOW MP600 centrifugal bypass filter is designed for an oil sump capacity of 190-1550 liters (41.8-341 gallons). The IOW bypass filters turn faster than any existing market product. The higher speeds of the IOW centrifugal filters separate solids from the lubrication oil quicker and more effectively than any other centrifugal bypass filter currently on the market. The IOW centrifuge bowl is completely sealed to avoid cross-contamination between the cleaned and dirty oil. With a unique central disc stack, the IOW MP600 centrifugal bypass filter significantly improves the separation efficiency — drawing out the smallest particles to the outer bowl wall.