Contaminants in lubrication oil could be costing you your machinery! These tiny particulates contaminate the lube oil, eventually making it no longer fit for purpose. Instead of lubricating surfaces and assisting smooth processes, the oil is actually causing corrosion and damage to engine components.

But without being able to see them, how do we measure, control, and eliminate these harmful contaminants within lube oil? Heavy equipment and machinery are one of the biggest purchases in industrial organizations; with high price tags, it makes sense to ensure your equipment is treated with care and your investment is protected.

Effective lubrication management by using a centrifugal oil filter leads to many benefits

Unfortunately, it is still common practice, within many industries, to combat these microscopic particulates by simply performing an oil change and presuming this then resolves the issue. This couldn’t be further from the truth! Even brand new lubrication oil already contains particles, they are collected when oil is stored improperly, and more are absorbed by the lube oil during the change. Not only is this not the best practice for your machinery, but it is an expensive and time-intensive option. If new oil isn’t clean, then how can we control these contaminants?

Improving ISO Cleanliness Codes

As with any problem, knowledge is power, and regular oil analysis allows the user to monitor the levels of contaminants in the lube oil, see trends and react accordingly. Contaminant levels are measured and represented using ISO cleanliness codes. The ISO cleanliness codes are derived from the International Standard ISO 4406:2017. The ISO code shows three sets of separated numbers. Reviewing these codes at regular intervals gives a good indicator of the condition of your oil. It’s not only oil you could be saving on, by improving your ISO codes you’re also extending the lifespan of your engine!

Analyzing oil samples can also assist in diagnosing where contamination occurs in your engine. Preventing damage before it can become an expensive repair is an essential part of implementing a controlled maintenance program. By targeting the root cause of machine wear and failure before the damage is done can create impressive savings, not just in the cost of parts, but also labor costs. By achieving the desired ISO cleanliness codes, machine uptime is increased, sustainability and system operations are improved, maintenance costs are lowered, and most importantly, equipment and machinery lifespans are extended, increasing their return on investment!

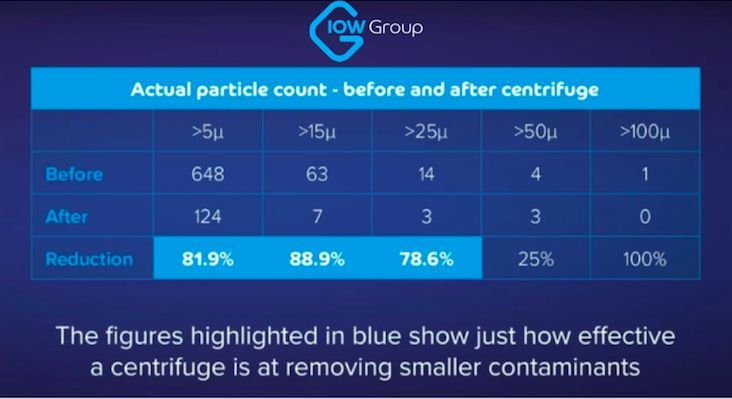

Another aspect of improving lube oil quality to protect your machinery is an effective filtration system, particles in oil are inevitable, but centrifugal oil separators can help to remove these and improve your ISO cleanliness code.

Centrifugal separators are bypass filters taking a small percentage of oil out of circulation, and using centrifugal force draws out

harmful contaminants that are then collected and disposed of when the centrifuge is full.

By using IOW patent protected filtration technology harmful particles are massively reduced and effectively protect your engine.

How can IOW Group extend the lifespan of your engine?

The IOW Group’s centrifuge filters have unique patent-protected features that make them 150% more efficient than any other centrifugal filter available. The IOW market-leading centrifuges are designed to stop any cross-contamination of clean and dirty oil. They use bowl disc technology to harness superior separation. With bowl disc technology, it can remove the smallest of contaminants. Combined with CentriClean remote monitoring units to ensure reliability and efficiency, the IOW centrifugal separator will have profound effects on processes and help your organization achieve ISO cleanliness code targets. IOW Group’s centrifuges run two-three ISO cleanliness codes better than the competition!

Recently a customer approached us looking to improve the cleanliness of the oil for their Caterpillar 3406 engine. Before installation, the ISO cleanliness code provided was 21/18/12, and we knew by using an IOW centrifugal oil separator, we could help in improving this! An IOW MP090 centrifuge filter was installed, and the results were fantastic! Managing to achieve a final ISO cleanliness code of 19/17/12. By using an engine life extension calculator, it showed that the lifespan of this Caterpillar 3406 engine had been extended x 1.5! This was a fantastic result, and the owner of this equipment was happy and satisfied that his investment was now being effectively protected, and this engine would now last much longer! Investing in an oil centrifuge now could save your engine in the long run.

Results from an IOW centrifuge filter installed on a CAT 3406 engine

ISO cleanliness codes are essential key indicators to improving reliability within your organizations equipment. Those that are focussed on increasing reliability strive to improve these codes.

You will quickly see the benefits of investing in an IOW centrifugal oil filter to achieve this.

Extend oil change intervals, extend the lifespan of your machinery and beat the competition using an IOW Group engine oil centrifuge.

To find out how we can help you fill in the contact form below.