Engines are critical to many industries as they power production and logistical processes worldwide. It is essential to maintain these engines for smooth and efficient operation. Oil filters are unsung heroes in removing contaminants such as dirt, metal particles, and carbon from engine oil, which would otherwise cause wear and reduce engine efficiency, leading to significant engine damage.

Bypass oil filters are fundamental for extending engine life and enhancing performance. Unlike standard full-flow filters, bypass oil filters capture the more abrasive, finer contaminants, including microscopic particles. By filtering out these particles, bypass filters reduce engine wear, ensure smoother operation, minimize breakdowns, and extend oil change intervals. Therefore, understanding how bypass systems work, and their benefits is essential for anyone dedicated to long-term engine health and efficiency.

What is a Bypass Oil Filter?

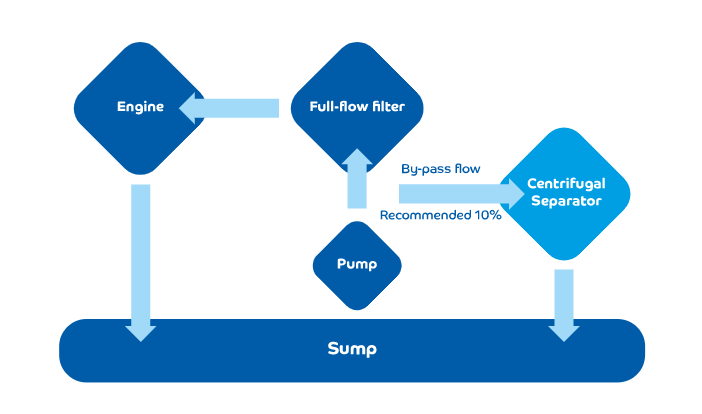

Bypass oil filters are supplementary filtration system used alongside primary full-flow filters in engines and machinery. While full-flow filters capture larger particles as oil circulates through the engine, they allow smaller, harmful particles to pass through. Bypass oil filters address this by filtering a small portion of the oil at a time, removing these finer contaminants. This dual filtration system significantly improves overall oil cleanliness, providing better engine protection and extending oil and engine life. A highly efficient type of bypass oil filter is the centrifugal filter. It is the most effective filtration device available, utilizing centrifugal force to separate microscopic particles from lubrication oil.

How Does a Bypass Oil Filter Work?

A bypass oil filter works by:

- Oil Diversion: As the engine or machinery operates, lubrication oil circulates throughout the engine/machinery to lubricate and clean components. A portion of this oil diverts from the main flow into the bypass filtration system, where smaller, more harmful particulates are filtered. Centrifugal filters are particularly effective at capturing these fine particles.

- Pressure Regulation: Typically, 10% or less of the total oil flow is directed through the bypass oil filter to prevent any significant pressure drop that could harm the engine.

- Filtration: Once the dirty oil enters the bypass oil filter, particulates are filtered to improve oil cleanliness. In the case of a centrifugal filter, particulates as small as a few microns are collected and removed from the oil.

- Return to Engine: After filtering, the cleaned oil is returned to the engine/machinery oil sump and recirculated through the system.

- Continuous Operation: This process repeats continuously as the engine runs, gradually filtering all the lubrication oil over time.

Advantages of Bypass Oil Filtration

- Enhanced Filtration: By removing finer particles from the lubrication oil, bypass filters ensure that cleaner oil circulates through the engine, reducing harmful particulate buildup and minimizing wear on critical components.

- Extended Oil Life: Cleaner oil reduces the frequency of oil changes, saving time and money on maintenance. This results in longer oil change intervals and lower overall maintenance costs.

- Improved Engine Protection and Reliability: By eliminating abrasive particles, bypass oil filters protect engine components, enhancing reliability and reducing likelihood of unexpected maintenance needs.

- Environmental Benefits: Fewer oil changes result in less oil waste, and cleaner oil promotes smoother engine operation, which can decrease fuel consumption and emissions, benefiting the environment.

- Maximized Return on Investment (ROI): Bypass oil filters reduce maintenance costs by minimizing the need for frequent oil changes and part replacements. Increased engine uptime and efficiency can enhance production, which makes bypass oil filters a wise investment.

In summary, bypass oil filtration significantly enhances oil filtration systems for engines and machinery by removing contaminants from the lubrication oil. This enhancement ensures better engine and machinery care, leading to improved efficiency while supporting sustainability initiatives. Beyond the initial investment, bypass oil filtration offers financial benefits by reducing maintenance needs and extending engine life.

IOW Group is a leader in oil filtration, offering advanced separation technology to industries worldwide. IOW Group supplies superior solutions that maximize return on investment with technology that is 150% more efficient than other bypass oil filters.

Contact us to find out how they can transform your oil filtration system with bypass filtration.