In the vast realm of industrial machinery, the heart of many operations lies within the efficiency of pumping systems. As industries evolve and demand increases, the choice of pump technology becomes a critical factor in ensuring seamless operation and optimal performance. Among these, high-quality triple screw pumps emerge as indispensable assets, offering a multitude of benefits that significantly impact the industrial landscape.

What is a Triple Screw Pump?

A triple screw pump (also known as a three-screw pump) is a type of positive displacement pump that is specifically designed for managing lubrication oil and similar non-explosive self-lubricating fluids. They are widely deployed in industrial settings across the energy, transportation, mining and marine sectors, integral to various processes. A triple screw pump comprises of a male driver (power rotor) and two female rotors (idler rotors) in constant rotation, propelled by a motor.

Triple screw pumps are known for their ability to provide smooth, pulsation-free flow, making them suitable for applications where precise fluid handling is required and are utilized for a variety of purposes, including:

- Transferring fluids

- Boosting pressure

- Lubrication systems

How does a Triple Screw Pump work?

The operation of a triple screw pump involves rotation of the rotors (or screws) within the pump casing. As the screws rotate, they trap fluid between the screw threads and pump casing, creating a series of sealed chambers. Once the pump is primed and filled, the liquid is drawn efficiently and facilitates the pump's fluid-handling capabilities. This movement effectively displaces the fluid from the suction side to the discharge side.

Why is Precision and Reliability Important in Triple Screw Pumps?

Reliability is crucial for triple screw pumps because they are often used in critical industrial processes where any breakdown or malfunction can lead to significant downtime, loss of production, and potentially costly repairs. Reliability in triple screw pumps is particularly important for:

- Continuous operation - any unexpected breakdown can disrupt entire processes, leading to production delays and financial losses; especially in applications where continuous operation is essential (such as oil refineries, chemical plants, and marine vessels).

- Cost efficiency - reliable pumps require less maintenance and repair, resulting in lower operational costs over time. Unplanned downtime and frequent repairs contribute to lost productivity and labor expenses.

- Handling hazardous materials - these pumps are often used to handle hazardous or sensitive fluids like lubricating oil, fuels, and chemicals. It's therefore vital that there are no leaks or spills, which can result in safety hazards, environmental damage, and regulatory violations.

- Longevity - triple screw pumps are designed to withstand harsh operating conditions, so a high-quality, reliable pump will therefore last longer and provide better return on investment for the owner.

Precision Engineering Meets Innovation

Precision engineering and innovation plays a crucial role in the design and development of triple screw pumps which leads to enhanced performance, efficiency, and reliability. Precision engineering ensures tight tolerances and clearances between the rotating components of the pump, such as the rotors and pump casing. This precision machining minimizes leakage and maximizes efficiency, reducing internal recirculation losses.

It is important to select materials with superior mechanical properties and corrosion resistance to withstand demanding operating conditions when producing triple screw pumps, ensuring durability and longevity of the pump itself. Innovative sealing technology also helps to minimize fluid leakage and enhance the pumps reliability for leak-free operation and reduced maintenance.

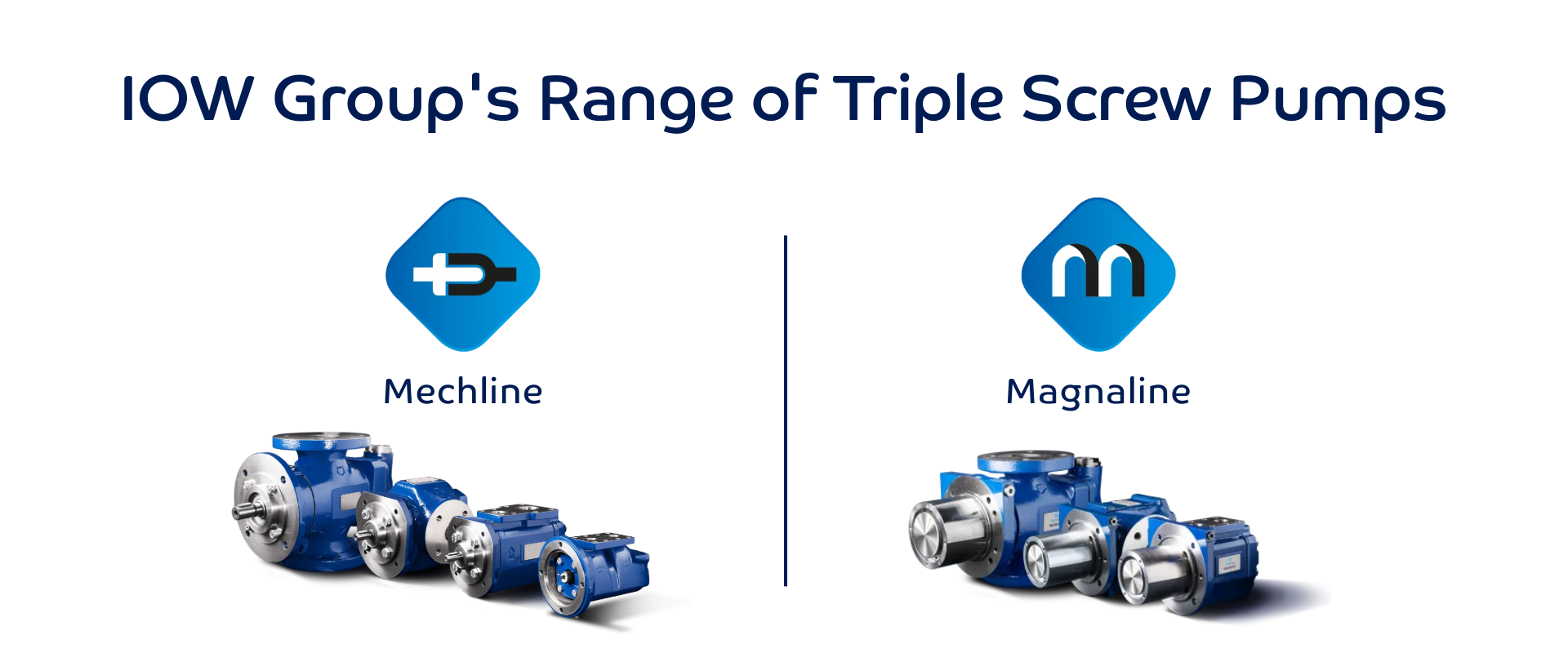

IOW Group's Range of Triple Screw Pumps

Precision engineering is the cornerstone of production at IOW Group. It guarantees only high-quality components are used to make up our pump range, for enhanced reliability and high-performance. Advancements in our Magnaline series enables us to provide customers with superior magnetically sealed pumps, ensuring completely leak-free operation. This feature not only keeps maintenance requirements significantly low, but it also simplifies installation through the magnets ability to self-align with little guidance.

As a company committed to delivering high-quality products, we implement a rigorous testing procedure using a state-of-the-art test rig to ensure that every pump leaving our facility has undergone thorough evaluation. This meticulous process guarantees customers receive flawless pumps that are ready for immediate use, providing peace of mind and confidence in IOW Group products.

Environmental Impact and Sustainability

Efficiency in pump technology doesn't just benefit the bottom line; it also aligns with sustainability goals. High-quality triple screw pumps are highly efficient, minimizing energy consumption during operation. Their positive displacement design and precise fluid handling capabilities establishes optimal performance, reducing overall energy requirements of pumping systems. This therefore has a knock-on effect with emissions, contributing to more sustainable operations.

Moreover, innovations in sealing technology, such as magnetic seals, enable triple screw pumps to operate with little or no leakage, preventing fluid spills reducing the risk of environmental contamination, ultimately protecting ecosystems and groundwater resources. Triple screw pumps are designed and manufactured to meet stringent environmental regulations and industry standards so compliance with these regulations ensures that pumps are environmentally responsible and safe for use in diverse applications.

Conclusion

Triple screw pumps play a vital role in numerous processes across various industries. Consequently, it's crucial for organizations to prioritize investment in top-quality, high-performance pumps to support their operations effectively. The significant impact of these pumps on cost efficiency, longevity, and environmental sustainability highlights their essential role as indispensable assets.

Contact the IOW Group

We will get back to you as soon as possible

Please try again later