eQlyps - the answer to total oil filtration

One compact, simple system that puts you in control.

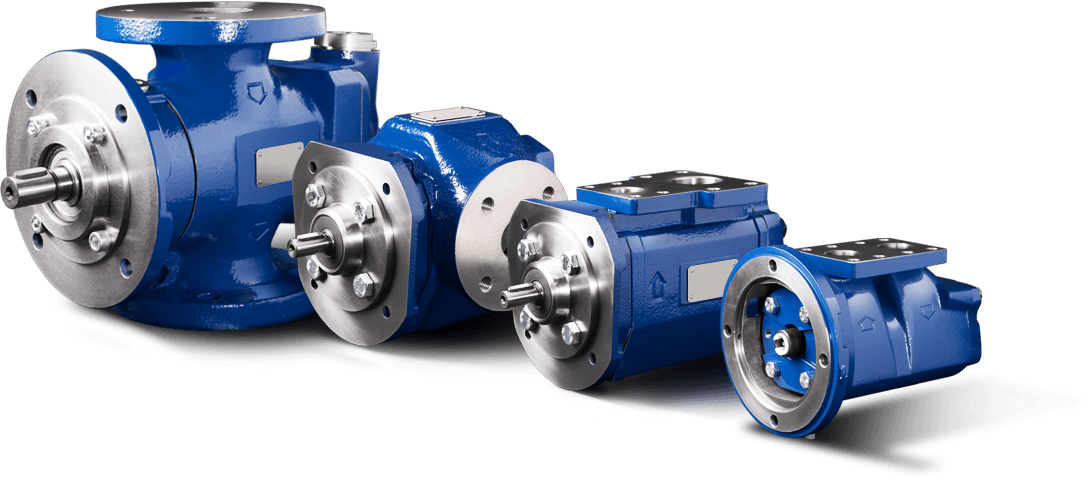

The IOW Group manufactures a full range of positive displacement triple screw pumps that exceed the qualities of market-leading products.

Mechline

A like-for-like pump replacement

Easily replace defective pumps with IOW Group's mechanically sealed pumps. They can be used for high or low temperature fluids and are manufactured to a higher standard than market-leading products - ensuring durability

Magnaline

Superior magnetically sealed pumps

Magnaline pumps are magnetically sealed and are completely leak-free. This keeps maintenance low and installation is easy, as there is no need for alignment of motor/pump.

The IOW Group answers some regularly asked

questions about our triple screw pumps

A triple screw pump is a simple type of positive displacement rotary pump for handling lubricating oil and other non-explosive self-lubricating liquids. They are often used in industrial processes within the energy, transport, mining, and marine markets. The pump consists of a male drive rotor (power rotor) and two female rotors (idler rotors) that turn continuously, driven by a motor. The rotors are housed tightly within the pump body. Once the pump is primed and full, the liquid is drawn through the rotors via sealed chambers by the female rotors.

Triple screw pumps work by having three rotating internal components within a close-fitting outer pump body. Triple screw pumps consist of three rotors, one power rotor (male rotor) and two idler rotors (female rotors). These turn continuously to transport and circulate liquids with lubricating properties (lube oils, fuel oils, synthetic and vegetable oils) lubrication oil. The fluid being pumped is also used as lubricant, so the viscosity of the medium is also important. The lubricating oil (or other self-lubricating liquid) is transferred through a series of sealed chambers, formed by the rotors turning within the pump until it reaches the outlet. The turning motion is generated by an electric motor or engine crankshaft.

Triple screw pumps are used across various industries such as manufacturing, transport, mining, marine, and energy markets. They are suited for multiple uses such as fuel injection, oil burners, hydraulics, lubrication, and circulation of pressurized viscous fluids.

Triple screw pumps are used for tasks such as handling diesel and fuel oil, lube oil transfer, circulating lubricants within a closed system, fuel oil separating or boiler boosting. They move lubricating fluids from one application to another via rotating internal components.

Screw pumps and gear pumps are suitable for similar tasks. Many people opt for gear pumps as they are what they know, but we are able to quote a triple screw pump alternative. Gear pumps are larger and take up more space, the rotation speed is limited, and suction capacity is less than a triple screw alternative. Gear pumps are noisier, more turbulent, and cause more vibrations. We would advise choosing a triple screw pump model to suit your needs where possible. Our team of experts will be able to help advise you on this. Get in touch here (link to contact page)

- Able to handle fluctuating flow rate and pressure without losing efficiency

- Screw pumps are smoother, lower vibration pumping

- Better suction capabilities

- Smaller footprint perfect for limited spaces

- Better mechanical efficiency

- Able to operate at higher motor speeds

A Mechline pump is a triple screw pump with a mechanical seal inside. A mechanical seal is a simple method of containing lubricating fluid within the triple screw pump. A mechanical seal maintains the pressure of the lubricating liquid being pumped, using sealing gaskets and O-rings to complete the seal, and withstand any friction caused by the rotor turning. In Mechline mechanically sealed pumps, a micro-gap is created within the seal to allow a leak path. The seal faces cannot be permitted to run dry as the frictional heat build-up will very quickly cause severe seal face damage and extensive leakage. All mechanical seals must leak to operate properly. This makes it impossible for a mechanical seal to be leak-free. The amount and visibility of the leakage will vary from pump to pump.

Mechline (mechanically sealed) triple screw pumps are typically lower-cost seals. They are an effective choice for creating a seal within the triple screw pump. By fitting a mechanical seal to your triple screw pump that is the optimum design size and material, you can extend the lifespan and productivity of your machinery/applications.

A Magnaline pump is a triple screw pump with a magnetic coupling adjoining the pump to the motor shaft. The drive is created by strong magnets found within the coupling between the triple screw pump and motor. Magnetic couplings help contain lubricating oil within the pump while maintaining the correct pressure for pumping the lubricating oil. Due to the strong magnetic force, there is no leakage with a Magnaline pump.

Magnaline (magnetically driven) triple screw pumps have no disposable seals. Therefore, they require less service and maintenance than a mechanical seal. Magnetic seals eliminate any leaking, ideal for environments where leaking liquid poses a risk. Eliminating consumable spares improves the pump’s performance, reliability, and efficiency. Installation of a Magnaline pump/magnetic coupling is easy, as there is no need for alignment of the pump and motor due to the strong magnetic force within the coupling.

Magnaline and Mechline pump both have their advantages; it depends upon the environment and customer requirements. Our team can advise which pump type best suits your needs and can quote you both the Mechline and Magnaline alternatives. If you need further information and want to discuss which pump type is best for you, contact our team.

IOW Group Mechline and Magnaline pumps are used in a wide range of applications and industries

Applications

- Supplying fuel and lubrication

- Transferring oil in refineries

- Used in large hydraulic systems

- Used for lubrication of gears, hydro turbines, turbines powered by steam or gas, and paper machines

Industries

- Marine

- Power Generation

- Trains, Trucks and Buses

- Agriculture

- Mining

- Construction

- Defense

- Oil and Gas

Contact the IOW Group

We will get back to you as soon as possible

Please try again later