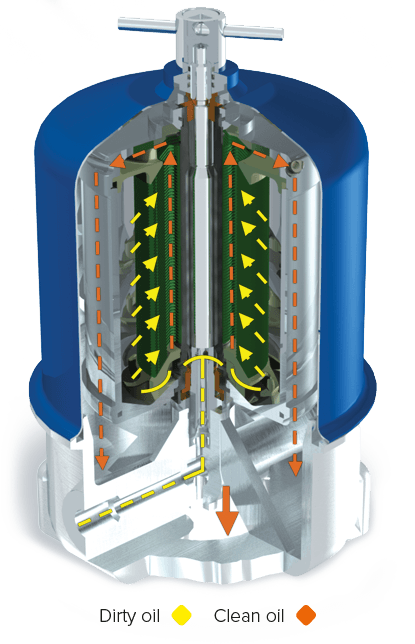

How an IOW Group MP centrifugal oil separator works

eQlyps - the answer to total oil filtration

One compact, simple system that puts you in control.

The highest performing and only self monitoring bypass oil filtration spinner type separators in the world. Watch our video of how this unique product works.

Unique solution

Oil is introduced into the separator bowl at engine oil pressure through holes drilled in the vertical spindle and via the accelerator channels in the bearing distributor.

The bowl then fills up and oil overflows into the top turbine where it exits the bowl via the four speed turbine channels and then out via the nozzles. This in turn rotates the bowl, generating the centrifugal force required to remove the contaminants from the oil.

The contaminants migrate towards the outside of the bowl where they are deposited on a removable oil resistant insert. The cleaned oil migrates towards the center of the bowl, where it is expelled by the nozzles in the top turbine, thus perpetuating the cycle.

Increased efficiency

Unlike conventional centrifugal spinners/separators, IOW Group separators use bowl discs to increase the efficiency of separation, dramatically reducing the time that contaminants can stay in the oil.

We have also improved the sealing between the dirty oil inlet and the cleaned oil outlet. This ensures that there is minimal cross-contamination between the two.

Save valuable man-hours

IOW Group centrifugal oil separators also have dirt/sludge monitoring technology, which informs the operator when the separator needs cleaning, saving valuable personnel time on otherwise unnecessary cleaning.

The system is both MODBUS and CANBUS compatible and can be easily connected to your existing alarm systems.

MP oil centrifugal separators provide significant benefits to sectors of industry using large reciprocating engines

The benefits

- Reduction in engine wear

- Reduction in use of lubricating oil

- Aids clean combustion for reduced exhaust emissions

- Saves man-hours in cleaning

- Reduced waste disposal costs

- Simple to operate and maintain

- Same day dispatch available on all spares

- Extends service intervals

- Extends life of full-flow filters

- Capital cost investment returned quickly

- Environmentally friendly

- Bolt-on/bolt-off for existing installations

Sectors

- Marine and power

- Automotive

- Trains, trucks and buses

- Agriculture

- Mining

- Construction

- Defense

Contact the IOW Group

We will get back to you as soon as possible

Please try again later